Unlocking the Potential of FDM 3D Printing in Product Development

FDM 3D printing is often overlooked when it comes to creating prototypes during the product development process. Yet, it has evolved into one of the most widely used and cost-effective methods of prototyping. FDM printers are now readily available, from local libraries and schools to makerspaces. However, don't be misled by their accessibility and affordability—FDM 3D prints can be invaluable assets in the journey of product development. At Bellair3D, we have honed our FDM printing expertise and understand the immense value this technology offers.

A Checkpoint in the Design Journey

In the product development cycle, it's common to spend months meticulously crafting CAD designs in pursuit of the "perfect" product. Subsequently, substantial investments are made in producing a batch of prototypes. More often than not, these prototypes unveil unforeseen issues: incorrect sizing, PCBs that don't fit, uncomfortable grips, assembly complexities, and a bewildering array of screws. FDM prototypes provide crucial checkpoints along the development path, empowering you to approach costly machine parts or cast prototypes with confidence. At Bellair3D, we work closely with you to manufacture these FDM checkpoints, keeping your development goals in clear focus.

Cost-Effective Prototyping

Compared to other prototyping methods, FDM printing is among the most cost-effective and approachable options. Our mission at Bellair3D is to make 3D printing accessible to all by providing cost-effective solutions that enable anyone to create physical parts.

Tangible Realization

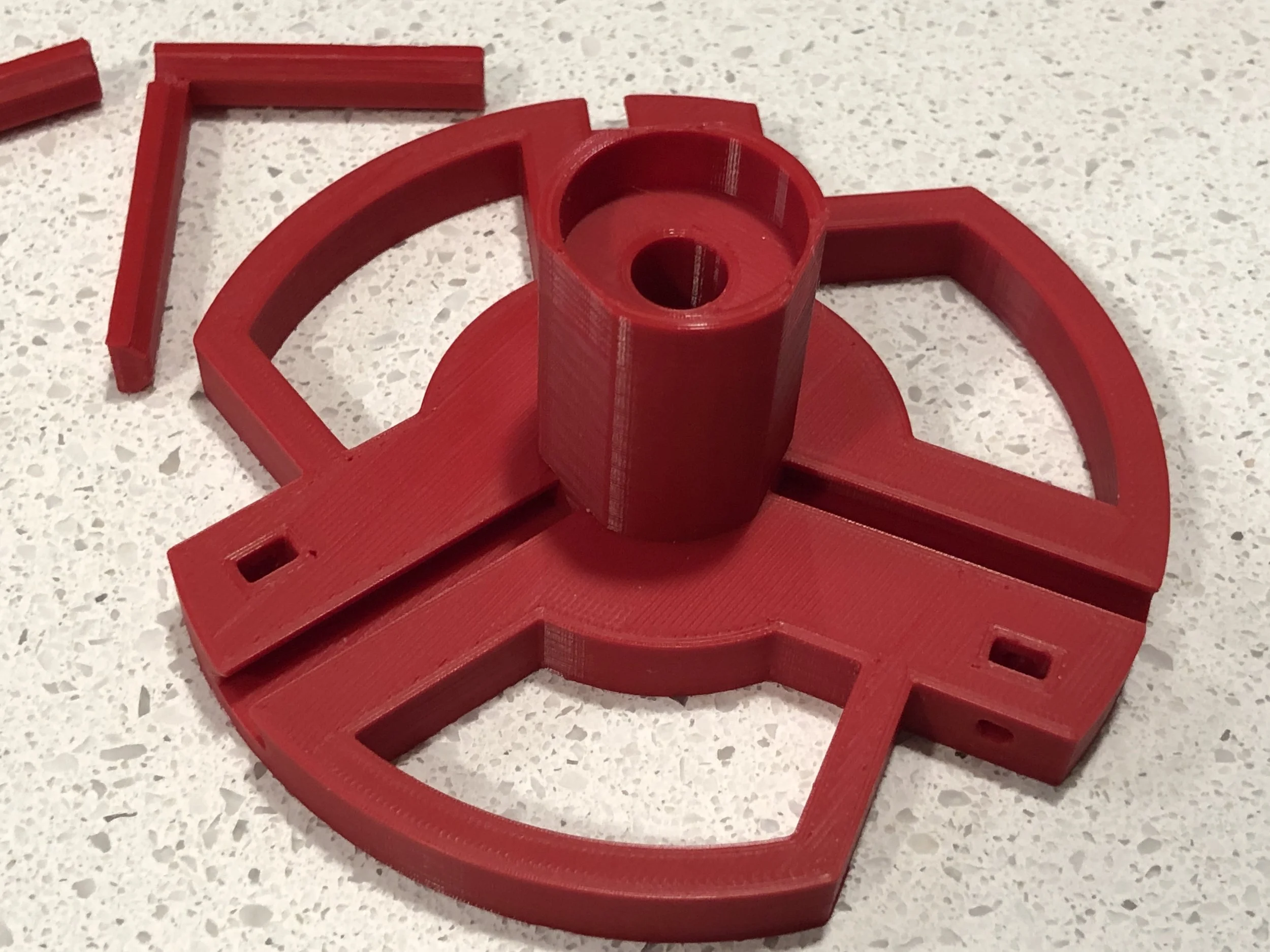

While CAD is a powerful tool for design, nothing can replace the experience of holding physical parts in your hands. Instead of investing months in creating something virtually, you can quickly produce and physically examine it. Just five minutes spent with physical parts can offer more insights than days in CAD could. FDM prints allow you to evaluate how various components fit together, user interactions with the product, ergonomics, weight, shape, form, and much more. They are also instrumental in confirming how a product assembles. While in CAD, you may have a series of screws holding down a panel, but creating a prototype could reveal that half the screws can't be installed because another part blocks access to them. This is a revelation that you can swiftly and easily attain with an FDM print, even if it wasn't apparent in CAD.

Conclusion: A Faster, More Informed Development Process

In your next product development endeavor, consider integrating FDM printing and physical prototypes into your development cycle. The affordability of FDM printing enables multiple prototypes, ultimately leading to the pursuit of the perfect design. The value of physically interacting with a part cannot be overstated; it serves as an assembly reference and provides insights that CAD alone cannot offer. Additionally, FDM prints are exceptionally fast, delivering parts in days instead of weeks, thus accelerating and enriching the development process.

So, reconsider the notion that FDM 3D printing is solely for hobbyists or educational institutions. At Bellair3D, we leverage FDM printing as a powerful tool that can significantly enhance your product development journey.